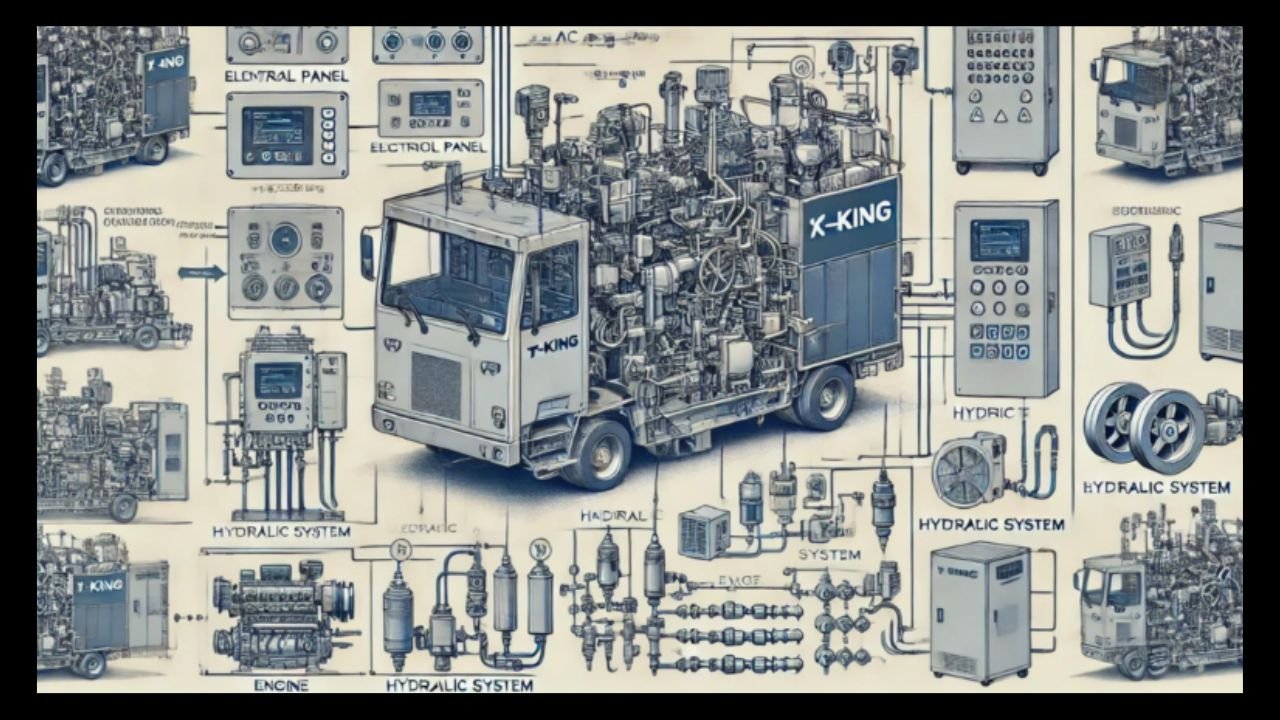

The T-King XAC-A8913 diagram is a critical tool in understanding the operation and setup of industrial equipment. Known for its precision and detailed representation, the diagram highlights all the essential components and their role in the machinery’s overall functionality. Used primarily by industrial engineers, maintenance technicians, and equipment operators, this diagram serves as a roadmap for troubleshooting, maintenance, and optimal equipment performance.

Industrial environments are continually evolving, with the need for equipment that’s both efficient and safe. The T-King XAC-A8913 diagram simplifies these complexities by visually communicating the inner workings of machinery. This post will explore the diagram’s components, applications, maintenance tips, and future advancements, leaving you with a complete understanding of its importance and practical use.

Understanding T-King XAC-A8913

The T-King XAC-A8913 is an advanced electrical schematic diagram designed to optimize the functionality and safety of industrial equipment. Acting as a comprehensive blueprint, it meticulously outlines the interconnections between various mechanical and electronic components, including control units, actuators, sensors, and safety mechanisms. With its high-resolution depiction of internal circuits and detailed labeling of each segment, the T-King XAC-A8913 serves as an essential tool for engineers and technicians. This diagram not only simplifies the process of machinery installation, operation, and maintenance but also enhances troubleshooting accuracy in complex industrial environments. By integrating modern technological principles, it supports efficiency improvements and risk mitigation within resource-intensive sectors.

Understanding the Components of the T-King XAC-A8913 Diagram

The T-King XAC-A8913 diagram is detailed and incorporates several essential components integral to industrial machinery. Here are the main elements:

Major Components

- Switch Panels

The switch panels form the operational backbone, designed for initiating or halting system functionality. They house control mechanisms that streamline operations.

- Circuit Breakers

These are vital for safety, designed to prevent overloads and short circuits. They ensure that the equipment operates within permissible electrical limits.

- Terminal Points (Connection Nodes)

Terminal points are designated spots for connecting wires or devices. These nodes ensure the seamless flow of electricity or signals across the machinery.

- Relays and Contactors

These act as the intermediaries for automation, controlling the flow of electricity between different components based on operational requirements.

- Indicator Lights

Designed to provide visual feedback, these lights inform the operator of the equipment’s status, ensuring safe and efficient operation.

Importance of Each Component

Each element in the T-King XAC-A8913 diagram plays a pivotal role in ensuring machinery runs efficiently:

- Prevent operational disruptions caused by misaligned connections.

- Enable faster identification of faults during breakdowns.

- Simplify the setup and installation of new components by providing a guide.

Understanding these components forms the foundation for effectively using and maintaining the equipment.

Practical Applications of the T-King XAC-A8913 Diagram

The T-King XAC-A8913 diagram has diverse applications across various industrial settings. Its versatility and clarity make it a vital tool in ensuring operational efficiency and safety.

Real-World Applications

Factory Automation Systems

The diagram is employed to integrate and manage automation equipment, ensuring seamless communication between robots, conveyors, and control systems.

Power Distribution Panels

It clarifies the intricate wiring of distribution panels, enabling efficient energy allocation without risks of overload or imbalance.

Manufacturing Assembly Lines

From automotive factories to electronics assembly lines, the T-King XAC-A8913 diagram aids in smooth machinery operation by mapping out control systems.

HVAC Systems

Heating, ventilation, and air-conditioning systems rely on the diagram for proper wiring and optimal functionality.

Case Studies

Enhanced Safety in a Manufacturing Plant

A leading electronics manufacturer implemented the T-King XAC-A8913 diagram to overhaul its assembly line. The diagram improved safety protocols by accurately identifying high-voltage zones and ensuring proper wiring, reducing accidents by 30%.

Efficiency in Energy Distribution

A large-scale power plant utilized the diagram to optimize its distribution panel layout. This change reduced downtime caused by faulty connections and saved approximately 15% on operational costs annually.

Maintenance and Troubleshooting Tips

Regular maintenance and timely troubleshooting are paramount to keeping equipment that uses the T-King XAC-A8913 diagram functioning optimally.

Maintenance Best Practices

- Regular Inspections

Periodically check for loose connections, corroded wires, or faulty components.

- Clean Contact Points

Ensure the terminal points are clean and free from dust or rust to prevent electrical failures.

- Update Documentation

Keep your T-King XAC-A8913 diagram updated with any machinery modifications or upgrades.

Common Issues and Troubleshooting Steps

Faulty Circuit Breakers

- Symptom: Frequent tripping of equipment.

- Solution: Check for overloads or replace damaged breakers.

Disconnected Wires

- Symptom: Equipment not starting.

- Solution: Use the diagram to trace the disconnected wire and securely reconnect it.

Indicator Light Failures

- Symptom: Misleading equipment status.

- Solution: Inspect bulbs for burnout or wiring issues around indicator circuits.

Future Developments and Upgrades

The T-King XAC-A8913 diagram is poised for significant advancements, driven by growing trends in digital transformation and Industry 4.0.

Anticipated Developments

- Digital Diagrams and Interactive Systems

The incorporation of augmented reality (AR) to showcase 3D diagrams on handheld devices will improve accessibility for troubleshooting in real-time.

- Enhanced Automation Integration

Future diagrams will better support complex automated systems, incorporating dynamic adjustments for smart equipment adaptations.

- Standardization Across Industries

An initiative to make the T-King XAC-A8913 diagram compatible with global standards will further widen its usability across diverse sectors.

Why These Advancements Matter

The evolving capabilities of the T-King XAC-A8913 diagram ensure it remains a critical tool for businesses striving for smarter, safer, and more efficient operations.

Empower Your Understanding with the T-King XAC-A8913 Diagram

The T-King XAC-A8913 diagram is more than just a technical schematic—it’s a practical tool that empowers engineers, technicians, and operators to enhance safety, efficiency, and system understanding. Whether you’re setting up machinery, troubleshooting a fault, or optimizing a process, this diagram holds the key to operational success.

Armed with this comprehensive guide, you’re now equipped to make your machinery run seamlessly. Stay committed to regular maintenance and stay ahead of the curve by keeping up with advancements in diagram technologies.

For detailed support and professional advice, consider consulting with industry experts who specialize in T-King XAC-A8913 diagram applications.

You May Also Like: 2023-1954: A Journey Through Time and its Fascinating Implications

Conclusion

In conclusion, the T-King XAC-A8913 diagram emerges as an indispensable component in the realm of industrial technology. Its ability to enhance safety, streamline operations, and facilitate preventive maintenance demonstrates its vital role in modern machinery management. Through detailed real-world applications and documented case studies, this guide underscores the diagram’s effectiveness in optimizing industrial processes. As industries lean towards more automated and interconnected systems, the diagram is set to evolve with digital advancements, ensuring it remains a powerful tool for future technologies. By integrating the insights from this article, professionals can harness the full potential of the T-King XAC-A8913 diagram, fostering environments that prioritize efficiency, safety, and innovation.

FAQs

What is the purpose of the T-King XAC-A8913 diagram?

The T-King XAC-A8913 diagram provides a visual guide for understanding and managing industrial equipment components, enhancing efficiency and safety.

How can I find errors using the T-King XAC-A8913 diagram?

The diagram enables quick fault identification by tracing electrical connections, helping locate loose wires, faulty breakers, or misaligned components.

What industries benefit from the T-King XAC-A8913 diagram?

Industries such as manufacturing, power plants, HVAC systems, and factory automation frequently use this diagram to streamline operations and troubleshooting.

Can I update the T-King XAC-A8913 diagram after modifications?

Yes, it’s highly recommended to update the diagram whenever machinery is modified to ensure accuracy and operational clarity.

Is the T-King XAC-A8913 diagram transitioning to digital formats?

Yes, future developments involve digital and AR versions, enhancing accessibility and real-time application for troubleshooting and system integration.