Direct-to-garment (DTG) printing technology has revolutionized the apparel industry, offering small business owners, graphic designers, and apparel brands unparalleled opportunities to produce high-quality, custom clothing efficiently. Whether you’re a seasoned entrepreneur or a designer looking to break into the market, DTG printing can empower you with tools to cater to the growing demand for personalized and sustainable fashion. This article dives deep into understanding r/DTG printing, its benefits, challenges, and future trends while showcasing success stories to guide you on your own path to success.

Understanding DTG Printing

What is DTG Printing?

DTG stands for direct-to-garment printing—a modern method of imprinting designs directly onto textiles using advanced inkjet technology. Unlike screen printing, DTG does not require creating stencils or screens for each design. Instead, designs are printed directly onto fabric, similar to printing an image on paper.

How DTG Technology Works

Here’s a quick overview of how DTG printers work:

- Design Preparation – Designers create or upload digital files onto compatible software. These designs are optimized for the garment in terms of size, resolution, and alignment.

- Pretreatment – The area to be printed on the garment undergoes pretreatment to prepare fabrics (especially dark colors) to ensure ink adherence and design longevity.

- Printing – DTG printers use inkjet heads to print the image directly onto the fabric in vibrant colors with a high degree of precision.

- Post-Processing – Once printed, the garment goes through a heat press to cure the inks and lock the design in place.

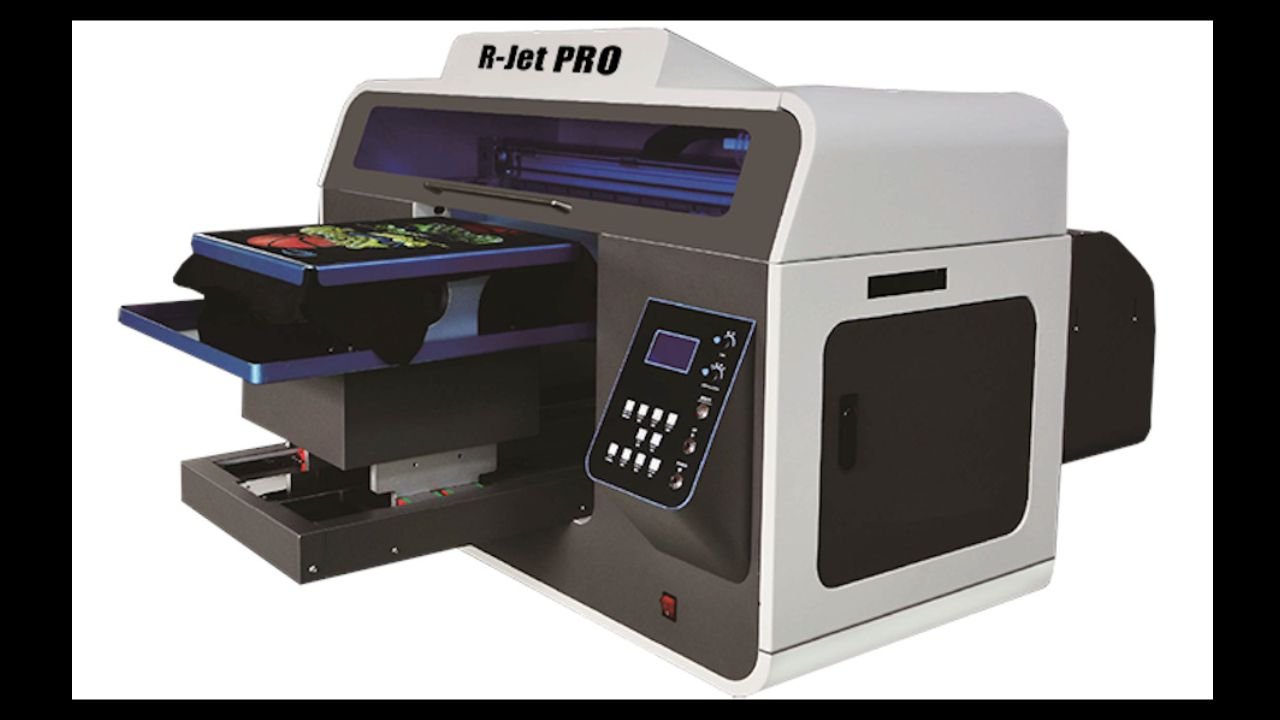

DTG Equipment and Ink Types

Using DTG printing requires equipment such as DTG printers, heat presses, and pretreatment machines. The inks used are water-based, eco-friendly, and designed to penetrate the fabric’s fibers without peeling or cracking. CMYK (cyan, magenta, yellow, and black) inks are standard, although white ink is needed for darker garments.

Versatility and Quality

DTG is a versatile option for creating intricate, full-color designs on various fabrics, including cotton, blends, and even some synthetics. The technique produces soft, durable prints that feel like part of the garment, boasting vibrant detail and resolution.

Benefits of DTG Printing

Why should small businesses, graphic designers, and apparel brands consider investing in DTG printing?

On-Demand Printing

Say goodbye to holding an inventory of bulk orders. DTG allows businesses to print only when there’s demand. This flexibility saves money on unsold inventory and enables smaller businesses to test new designs with minimal risk.

Unparalleled Customization

DTG thrives at creating custom, one-off pieces. Whether it’s a personalized birthday T-shirt or specially designed merch for an artist, DTG meets your customers’ unique demands.

Environmentally Sustainable

Because DTG printing is largely on-demand and utilizes water-based inks, it significantly reduces waste compared to traditional printing methods. Small batch production results in minimal leftover inventory and fewer unused resources.

Faster Turnarounds

With no need to set up screens or masks, the end-to-end process is much quicker, making DTG perfect for tight deadlines or fast-paced eCommerce businesses.

Superior Print Quality

DTG excels at producing vibrant designs with gradients, small details, and intricate patterns that are hard to replicate through other printing techniques.

Target Market Analysis

Who Benefits from DTG Printing Services?

DTG printing services cater to a diverse range of audiences:

- Startups & Small Businesses – Entrepreneurs can create limited edition runs or launch custom designs without large initial investments.

- Graphic Designers & Artists – Showcase creativity with customized prints that reflect original work.

- Apparel Brands – Target niche markets offering custom or trendy designs for limited drops.

- Event Organizers – Produce personalized merchandise for conferences, fundraisers, and sports events.

Seasonal Opportunities

DTG printing businesses often see spikes during events and holidays (e.g., personalized Valentine’s Day gifts or corporate Christmas merchandise). Seasonal designs can boost sales and attract specific buyers.

Overcoming Challenges

Addressing Common Hurdles

Although DTG printing is a powerful tool, it comes with challenges. Here’s how to tackle them effectively.

- High Initial Investment

Top-of-the-line DTG printers can be costly. However, leasing or exploring financing options can help businesses spread out the cost.

- Printing on Dark Fabrics

Pretreatment challenges or poor ink adhesion are common issues. High-quality pretreatment sprays and white ink resolutions can solve this.

- Maintenance

Regularly cleaning print heads and running maintenance cycles will ensure your DTG equipment runs smoothly and reduces downtime.

Practical Tips

- Start small with basic machines and scale up over time as orders grow.

- Test designs thoroughly, especially on different fabrics, before offering them to customers.

Success Stories of DTG Printing

Case Study 1: From College Passion to Profit

A college duo started their custom T-shirt business using an entry-level DTG printer. With their designs targeted at local events and eSports tournaments, they tripled their revenue within a year.

Case Study 2: Rebranding Through DTG

An eco-conscious activewear brand transitioned from screen printing to DTG to reduce waste. Their “green campaign” helped it stand out as a champion of sustainability, increasing customer loyalty.

Case Study 3: A Designer’s Merch Line

A freelance graphic designer launched a DTG-based merchandise line for her digital art. Offering personalized illustrations on hoodies, she grew her audience tenfold, driving eCommerce sales.

Future Trends in DTG Technology

Looking ahead, DTG printing will continue to evolve.

- Eco-Friendly Innovations

Manufacturers are developing bio-based and compostable inks to reduce environmental impact further.

- Printing on Expanded Fabrics

Expect better compatibility for fabrics like silk, polyester, and denim.

- AI-Powered Design Tools

Integrated design tools may soon leverage AI to create optimized layouts, automating much of the creative process.

Creating Your DTG Printing Success

DTG printing is an exciting avenue for creating high-quality, custom products efficiently. Whether you’re a business owner, a designer with a creative spark, or an apparel entrepreneur, DTG’s flexibility and growing capabilities make it a valuable investment. Keep ahead of trends, overcome challenges with innovative tools, and focus on sustainability to thrive in this dynamic field.

If you’re looking to explore r/DTG printing further or start your own business, there’s no better time to roll up your sleeves and jump in.

You May Also Like: Free Tablet with EBT Get the Tech You Need

Conclusion

In conclusion, r/DTG printing technology has emerged as a game-changer for businesses, designers, and apparel entrepreneurs. Its ability to create high-quality, custom products efficiently has revolutionized the industry and opened up new possibilities for customization and innovation. With its versatility and growing capabilities, r/DTG printing offers a valuable investment for those looking to stay ahead of trends and overcome challenges in this dynamic field. Moreover, its focus on sustainability aligns with the increasing demand for eco-friendly practices in the printing industry. Whether you’re exploring r/DTG printing further or considering starting your own business, now is the perfect time to take advantage of this cutting-edge technology and unleash your creativity. Embrace the power of r/DTG printing and pave your way to success in the world of custom apparel.

FAQs

What is r/DTG printing?

r/DTG printing stands for Direct-to-Garment printing, which uses inkjet technology to print designs directly onto fabrics with vibrant quality and precision.

Is DTG printing sustainable?

Yes, DTG is environmentally friendly. Its on-demand nature reduces waste, and its water-based inks are less harmful to the planet than traditional methods.

What fabrics are best for DTG printing?

DTG works best on natural fabrics like cotton or cotton blends and is gradually expanding to accommodate synthetics and silks with newer technology.

Is DTG printing profitable for small businesses?

DTG is highly profitable due to low production costs, on-demand capabilities, and the growing demand for custom, high-quality apparel.

What’s the difference between DTG and screen printing?

Unlike screen printing, DTG doesn’t require creating stencils, making it faster and more cost-efficient for detailed, colorful designs with small batch sizes.